CO2 Capture

The InnoSepra carbon dioxide capture technology can capture carbon dioxide from a number of sources including coal and natural gas based power plants. The innovative technology based on physical sorbents results in more than 40% reduction in capital and operating cost and can make carbon capture viable for a number of applications. In a DOE funded project the technology has been successfully demonstrated in a coal-fired power plant at one ton per day scale. The projected CO2 capture cost of less than $40/ton is very attractive for Enhanced Oil Recovery (EOR) applications. The technology development has been primarily funded by US Department of Energy and with additional funding from NJEDA, InnoSepra, and several strategic partners.

CO2 Capture Technologies

Post Combustion Capture Using Physical Sorbents

InnoSepra’s Post Combustion Technologies are based on physical sorbents that have much lower regeneration energy requirement compared to reaction based solvent and sorbent systems. These materials are also low cost and very stable. Through a combination of materials and process, InnoSepra has been able to develop lower cost carbon capture solutions. Unlike membrane and absorption based technologies, the InnoSepra technology produces pipeline quality carbon dioxide.

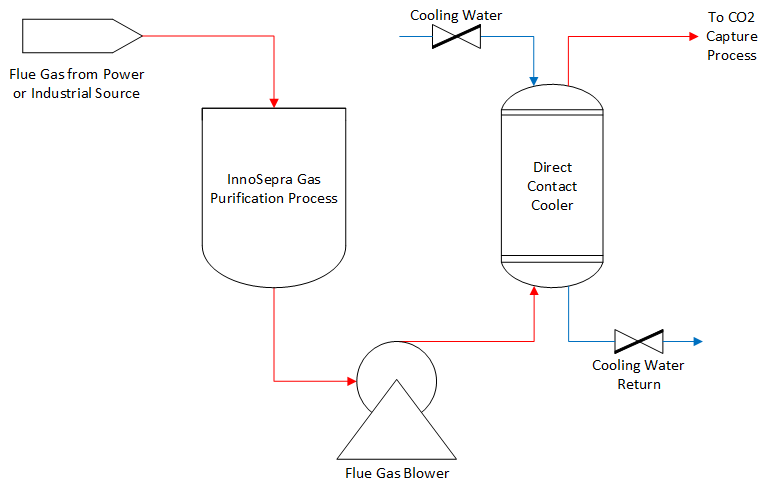

Flue Gas Purification

Acid gas impurities such as SOx and NO2 in flue gas can have a significant detrimental impact on solvent based capture technologies. InnoSepra’s flue gas purification technology can remove SOx and NO2 to sub-ppm levels while removing a significant amount of aerosols from the flue gas. This technology has been successfully tested at 500-scfm scale at a coal fired power plant and can greatly benefit any capture technology, particularly those based on reactive solvents.

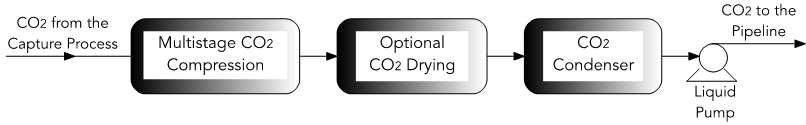

CO2 Compression

For any capture technology a significant amount of energy and capital is needed to bring captured CO2 to the pipeline pressure. InnoSepra has developed a CO2 capture and liquefaction cycle that can reduce the CO2 compression cost and energy requirement cost compared to current CO2 compression technologies by more than 20%.

CO2 Capture Markets

While CO2 capture has been recognized as one of the key technologies to mitigate the adverse impacts of global warming, there are very few places around the world that provide financial incentives for CO2 capture. One of the few incentives include 45Q tax credits in the United States. The 45Q addresses two specific markets.

Enhanced Oil Recovery

Capture of carbon dioxide from flue gases, oil gas operations and various industrial sources and using it for enhanced oil recovery has a lower carbon footprint than producing oil without the use of carbon dioxide. This application can potentially use all the carbon emissions from 30 MW of coal-based power generation for over 30 years. Additionally more than 70% of injected carbon dioxide is stored in the oilfields. The use of captured CO2 for oil recovery can provide a very economical and environmentally responsible solution for oil production and can prevent a significant amount of CO2 from being emitted into the atmosphere. The 45Q provides a tax credit incentive of up to $35/ton for utilizing captured carbon dioxide for enhanced oil recovery. Read more »

Carbon Dioxide Sequestration

In addition to utilizing carbon dioxide for enhanced oil recovery, the captured carbon dioxide can also be injected into suitable geologic formations for long term storage. The 45Q provides a tax credit incentive of up to $50/ton for utilizing captured carbon dioxide for long term geologic sequestration.

CO2 Capture Demonstrations

Bench Scale Testing at NRG’s Indian River Power Plant

The first generation Post Combustion Capture Technology was tested at NRG's Indian River Power Plant. The testing confirmed that the InnoSepra technology can directly provide pipeline quality CO2 (greater than 98.5% purity, less than 1 ppm moisture, less than 10 ppm O2). The CO2 capture efficiency was more than 94%. A detailed engineering analysis indicated at least 60% lower power loss due to steam extraction compared to MEA (monoethanolamine).

Flue Gas Purification Demonstration at the Abbott Power Plant

In addition to developing its own carbon capture technology, InnoSepra is also developing technologies that can benefit other carbon capture technologies. One of these technologies is the technology for flue gas purification prior to utilizing it for solvent based carbon capture. InnoSepra has demonstrated its flue gas purification technology at the Abbott Power Plant in Illinois as part of a DOE funded Linde project. During a long term test, the InnoSepra technology was able to remove both SOx and NO2 to sub-ppm levels. The incoming flue gas contained more than 100 ppm SOx and more than 10 ppm NO2. Between 50-80% removal of aerosols was also observed. Flue gas purification using InnoSepra technology can significantly reduce solvent degradation and aerosols emissions from the solvent-based capture processes.

Scale Up Testing at Technology Centre Mongstad (TCM)

The second generation InnoSepra Post Combustion Capture Technology can reduce the absolute parasitic power for CO2 capture to below 1.8 GJ/tonne. This technology primarily funded by US DOE is being demonstrated at TCM at 500 nm3/hr scale using RFCC flue gas. The technology has potential to reduce power loss due to steam extraction by more than 70% compared to MEA.

CO2 Capture Value Proposition

While near term carbon capture projects are likely to utilize solvent based solutions because of their relative maturity, the medium to longer term projects will need lower cost solutions for widespread deployment. The InnoSepra technology provides one such solution. The Second Generation InnoSepra Technology has significantly lower capital (>40%) and power requirements (>45%) compared to solvent based solutions and can reduce the carbon capture cost by more than 40%. This could lead to more extensive deployment of carbon capture in various industrial and power applications.